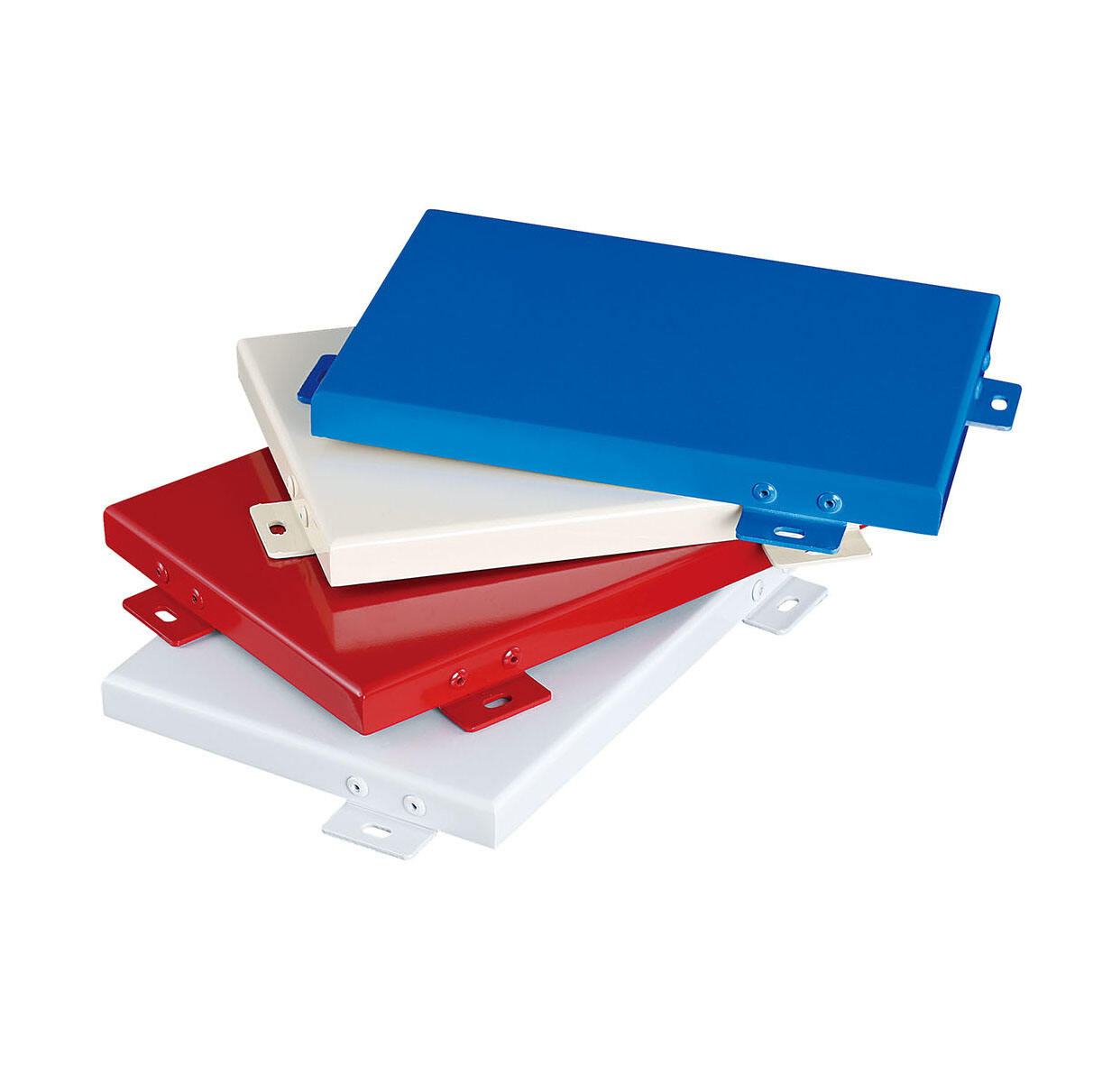

Exceptional Durability and Weather Resistance

Aluminium composite sheets excel in their ability to withstand harsh environmental conditions while maintaining their structural integrity and appearance. The sheets feature a specialized coating system that provides superior protection against UV radiation, preventing color fading and material degradation even after years of sun exposure. The aluminium layers offer inherent resistance to corrosion, while the bonding technology ensures that the layers remain firmly attached even under extreme temperature variations. This remarkable durability translates to a longer lifespan, reducing replacement frequency and overall maintenance costs. The material's resistance to chemical exposure makes it suitable for industrial environments, while its ability to withstand temperature extremes from -50°C to +80°C ensures reliable performance in various climates. The sheets' surface treatment also provides excellent resistance to scratching and impact, maintaining their attractive appearance even in high-traffic areas.