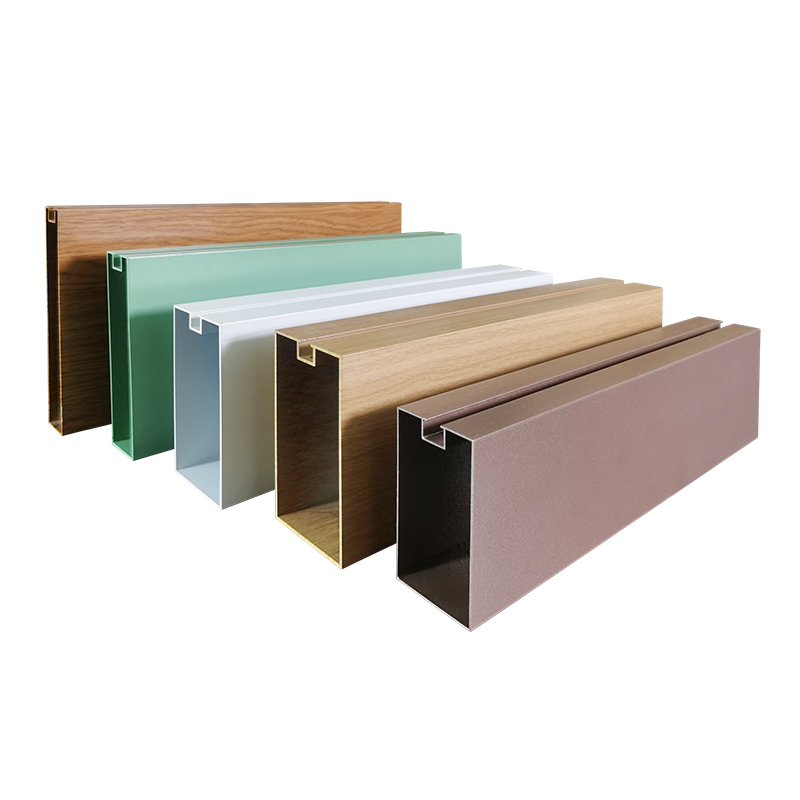

Superior Strength and Durability

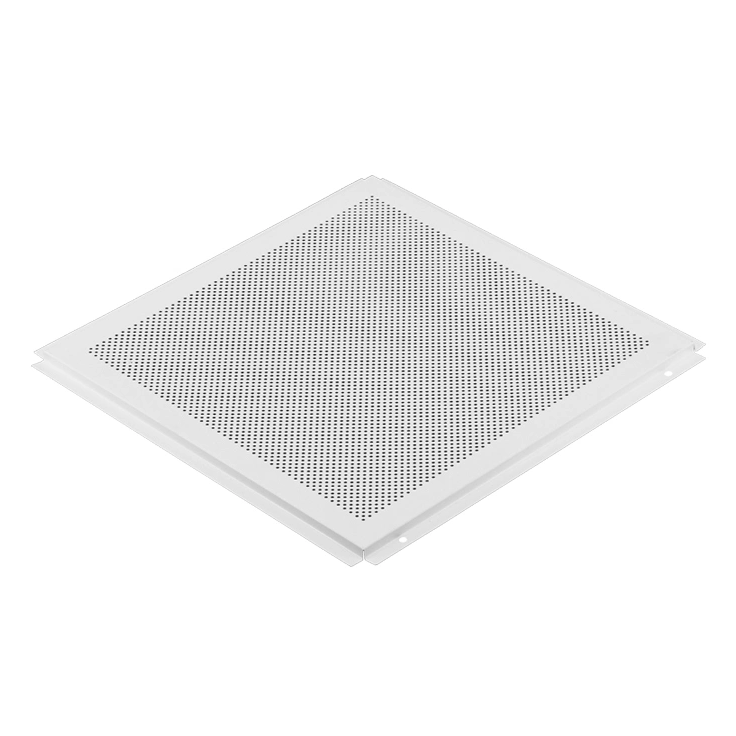

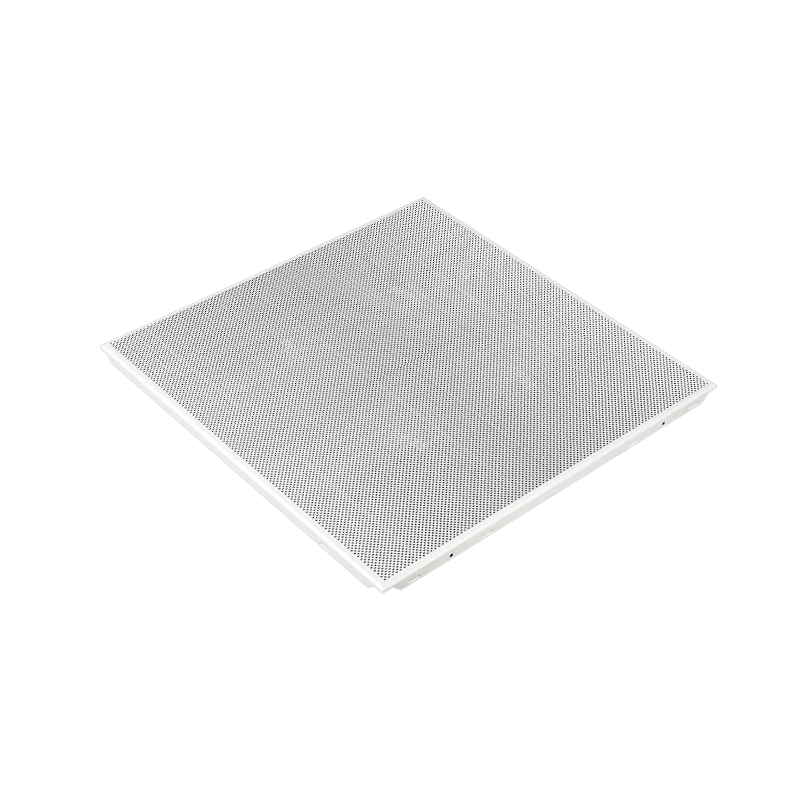

Expanded metal's unique manufacturing process creates an incredibly robust structure that outperforms traditional solid sheets in many applications. The stretching process aligns the metal's molecular structure, enhancing its inherent strength without adding weight. This results in a material that can withstand significant loads, impact, and environmental stresses while maintaining its structural integrity. The diamond-shaped pattern distributes forces evenly across the surface, preventing localized stress points and extending the material's lifespan. The enhanced strength-to-weight ratio makes it particularly valuable in construction and industrial applications where structural performance is crucial.