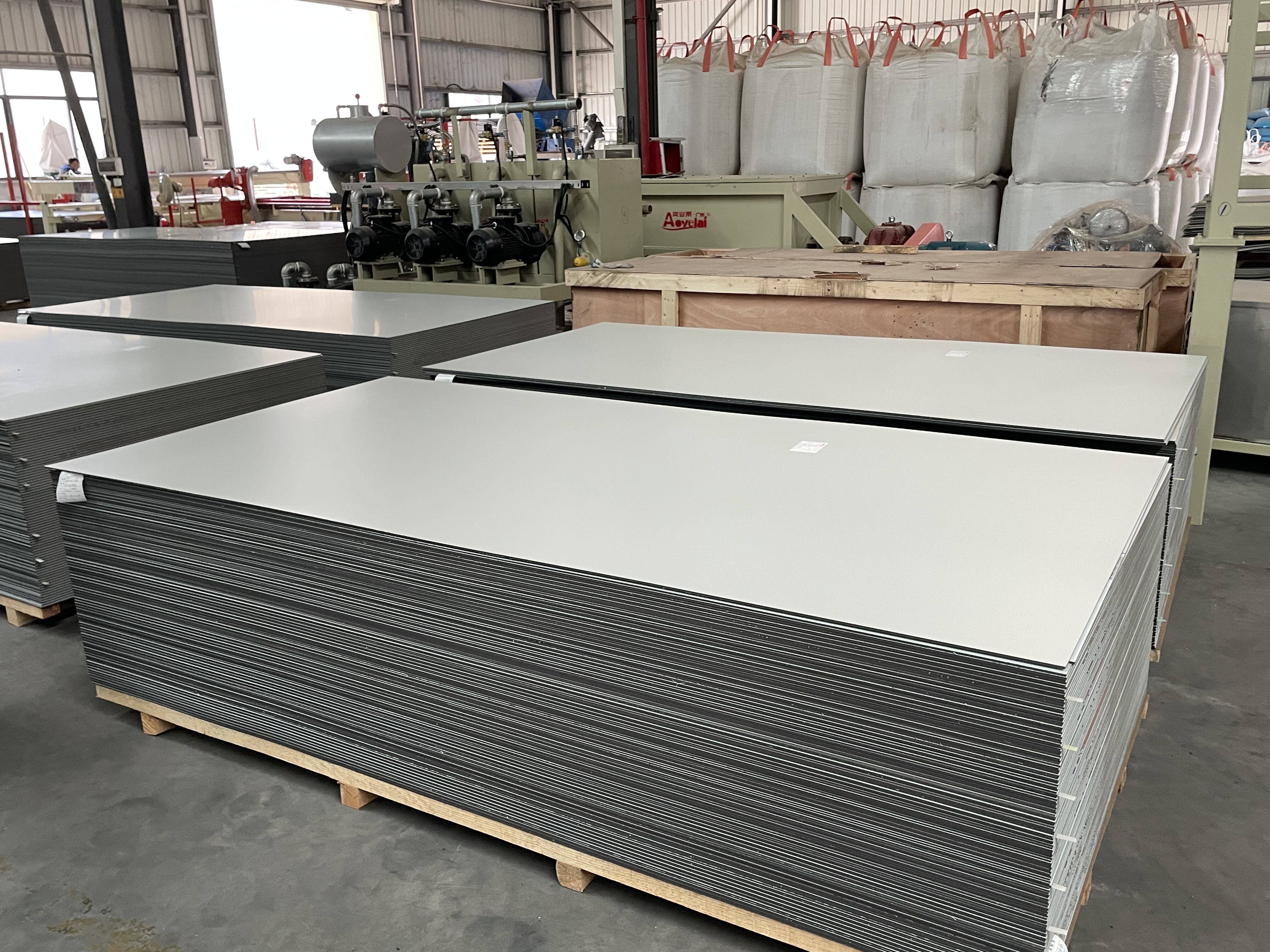

Superior Structural Performance

The honeycomb aluminum sheet's exceptional structural performance stems from its innovative design that maximizes strength while minimizing material usage. The hexagonal cell structure, when bonded between aluminum face sheets, creates a sandwich panel that exhibits remarkable resistance to compression, shear, and bending forces. This configuration allows for optimal load distribution across the entire panel, preventing localized stress concentrations that could lead to structural failure. The material's high stiffness-to-weight ratio enables it to maintain structural integrity under various loading conditions while remaining significantly lighter than solid alternatives. This characteristic is particularly valuable in applications where weight reduction is crucial, such as aerospace components or architectural facades. The uniform cell structure ensures consistent performance throughout the panel, while the aluminum composition provides inherent resistance to environmental factors that could compromise structural integrity.