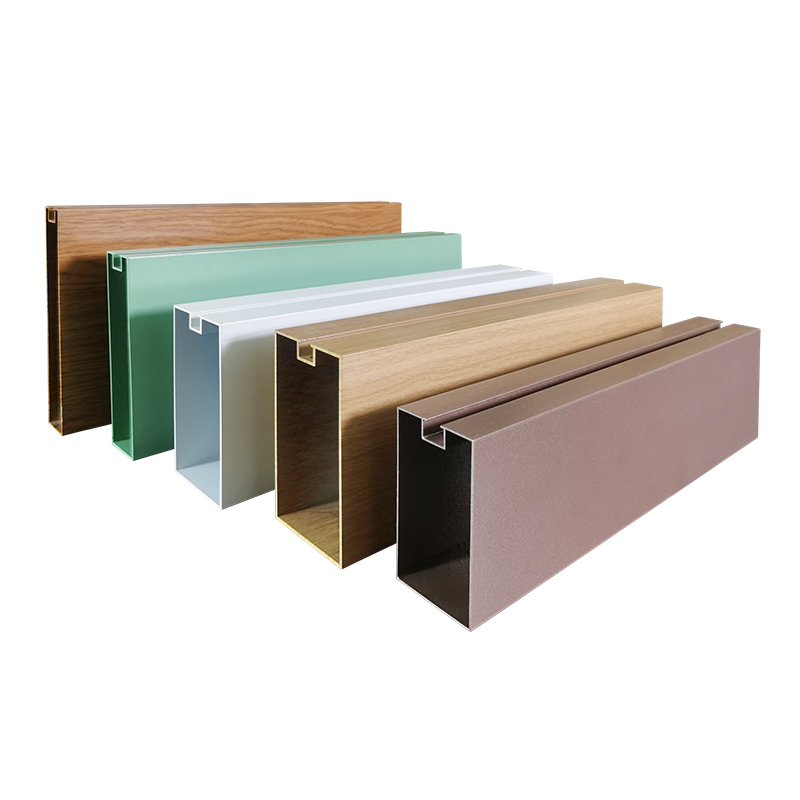

ประสิทธิภาพโครงสร้างที่เหนือกว่า

อัลูมิเนียมโปรไฟล์มีความโดดเด่นในงานโครงสร้าง เนื่องจากมีอัตราส่วนความแข็งแรงต่อน้ำหนักที่ยอดเยี่ยม ซึ่งสูงกว่าวัสดุก่อสร้างแบบดั้งเดิมหลายชนิด คุณสมบัตินี้ช่วยให้นักออกแบบและวิศวกรมีโอกาสสร้างโครงสร้างที่มีน้ำหนักเบาแต่ยังคงความแข็งแรง โดยไม่ต้องแลกกับความมั่นคงคงทน สามารถออกแบบเรขาคณิตภายในของโปรไฟล์ให้มีความเหมาะสมที่สุด เพื่อเพิ่มความแข็งแรงสูงสุด พร้อมทั้งลดการใช้วัสดุให้น้อยที่สุด ส่งผลให้ได้แนวทางแก้ปัญหาที่ประหยัดต้นทุนสำหรับการใช้งานที่ต้องรับน้ำหนักต่าง ๆ นอกจากนี้ วัสดุยังมีคุณสมบัติ inherent ที่สามารถรักษาความสมบูรณ์ของโครงสร้างไว้ได้ในช่วงอุณหภูมิกว้าง จึงเหมาะสำหรับการติดตั้งทั้งภายในและภายนอกอาคาร การผสมโลหะขั้นสูงยังช่วยเพิ่มคุณสมบัติทางกลของโปรไฟล์ ทำให้มีความต้านทานการเกิดความล้าและรูปทรงโครงสร้างเสียรูปจากแรงกดดันได้อย่างยอดเยี่ยม